Product info

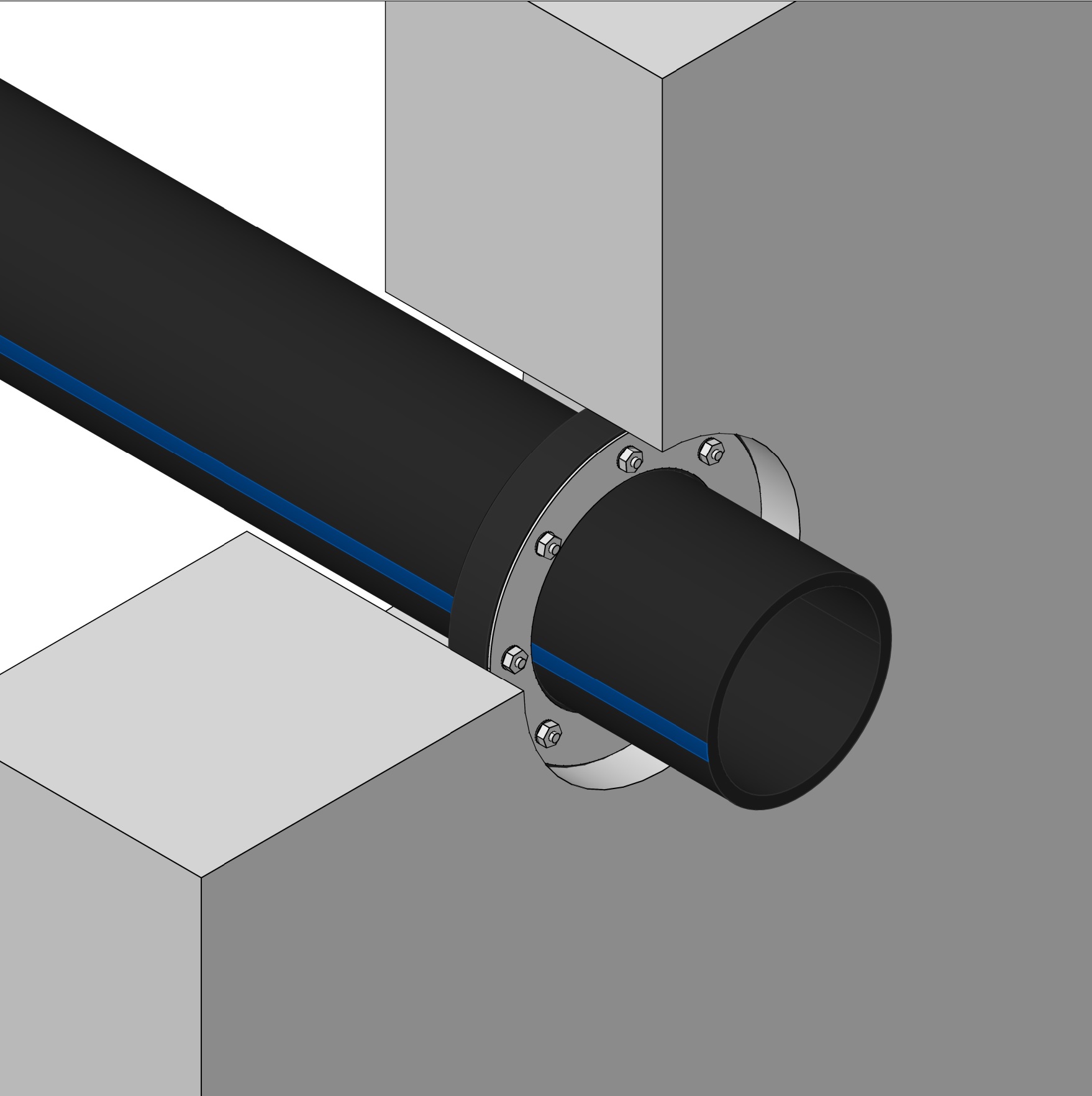

The annular space seal Hydrocord™ UKP Standard is the optimal product, perfectly sealing penetrations for pipelines of various purposes (gas, water, sewage) and the cables from pressure and non-pressure groundwater. Compression plates are made of stainless steel.

The annular space seal Hydrocord™ UKP can be detachable — Split version, which is used for already installed pipes and when it is not possible to mount the seal from the pipe end.

For Hydrocord™ UKP products, EPDM rubber is used as standard material, and pressure plates are made of S304 stainless steel.

Download

Application

Hydrocord™ UKP seal is used for sealing and waterproofing penetrations of sewerage, water supply, heat supply and other networks through the enclosing structures of buildings (usually monolithic or prefabricated reinforced concrete walls and ceilings), as well as for sealing penetrations of networks in cases during trenchless laying of pipes.

The principle of seal operation is the expansion of the sealing element (rubber core), under the action of the compressive force of the pressure steel plates when tightening the bolts that unite the structure.

Advantages

- Proven water resistance up to 5 bar;

- Installation does not depend on ambient temperature;

- Instrumental quality control (Dynamometric wrench);

- Gas and waterproof;

- Fast installation;

- Durability;

- Can be made to order, any size and modifications are possible;

- Modification for contact with oils and oil products (made of oil and petrol resistant rubber) is possible;

- Application in contact with drinking water is possible (modification with food rubber;

- • Modification with an extended operating temperature range (from -60°C to + 200°C) made of silicone rubber is possible.

Notes

- The drilled hole must be treated with epoxy compound;

- Hydrocord™ UKP should not support the pipe;

- The pipe must be centered and fixed on special pipe supports;

Materials

Annular space seal Hydrocord™ UKP can be made of the following materials:

- EPDM (Standard);

- Oil and petrol resistant rubber (Optional);

- Food grade rubber (Optional);

- Silicone caoutchouc for high temperatures (Optional);

Installation

- Clean the hole (sleeve, drilled hole, case, etc.) and pipe;

- Check the pipe and hole diameters and compare with the seal diameters;

- Install Hydrocord™ UKP on the pipe (for the Split version — close and assemble the seal on the pipe;

- Put the seal into the hole. The nuts of the tightening bolts must be directed towards the installer. (It is recommended to install the seal in such a way to provide access to the tightening nuts during the building operation);

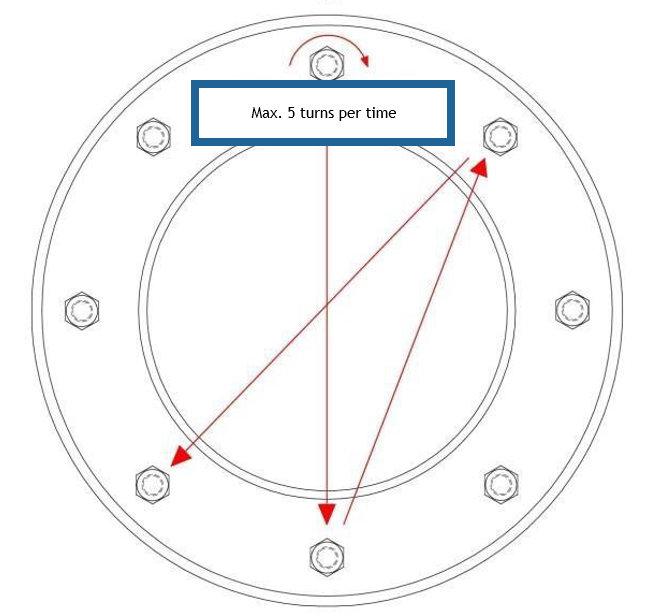

- Using a torque wrench, tighten the tie bolts in a star pattern (image below). The tightening torque must be in accordance with the table below. Each bolt must be tightened in several passes until the required torque is reached, several passes are required;

- It is allowed to mount the seal on pipes that are installed under a longitudinal slope of up to 30 (or up to 50‰).

HIGH COMPACTION RATE

Annular space seals create a high degree of seal (up to 5 bar) between the pipe and the hole, which allows you to reliably seal pipe penetrations.

RELIABILITY

The annular space seals are made of high quality materials (such as S304 stainless steel, EPDM rubber), which ensures a high degree of durability.

INSTRUMENTAL QUALITY CONTROL

The annular space seals are mounted using a torque wrench, which ensures instrumental quality control and achievement of the required seal in Nm.

EASY INSTALLATION

The annular space seals are easily and quickly installed in the structure. Seasonality does not matter, they can be installed even in frost.